Comprehensive Brazing Services

Your quest for top-tier brazing companies brings you to Byron Products. As industry leaders, we offer an extensive range of brazing solutions, uniquely tailored to answer your specific needs, from nickel and silver to copper, gold, and alloys with these elements. We believe in delivering solutions that can handle the versatility of your needs, including custom orders that challenge the boundaries of our capabilities.

With our wide array of vacuum and atmosphere furnaces, you can rely on us for quick, cost-efficient processing of your parts. Whether your need is vacuum brazing, continuous furnace brazing, honeycomb brazing, or induction and torch brazing, our team of highly trained and certified operators will ensure your exact specifications are met.

Vacuum Brazing

Equipped with vacuum brazing furnaces of varying sizes, we excel in processing parts under high vacuum or partial pressure conditions, resulting in clean and vibrant finishes. This flexibility ensures we can accommodate projects of all sizes, delivering a service that blends speed and competitive pricing, while focusing on custom solutions tailored to your unique requirements.

Continuous Furnace Brazing

Our continuous furnaces excel in handling your high-volume copper, silver, nickel, and gold brazing, as well as the brazing of other alloys that combine or contain these metals. Our furnaces are equipped with a variety of gasses, such as hydrogen, nitrogen, and dissociated ammonia atmosphere control, that provide consistent and bright results. With this efficient and seamless process, we’re ready to meet your diverse and high-volume production demands, ensuring customer satisfaction every step of the way.

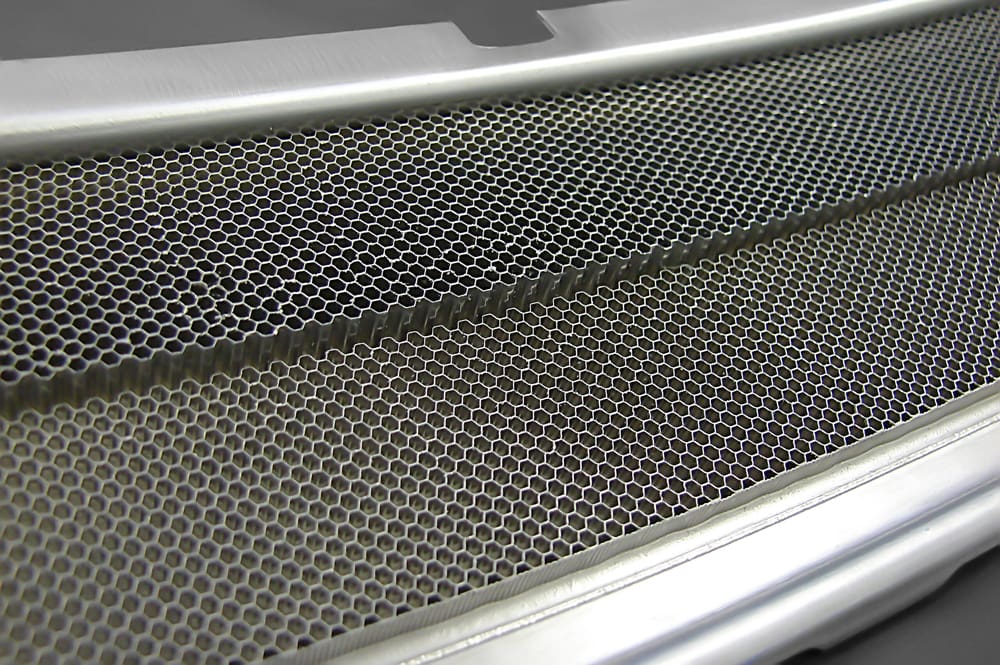

Honeycomb Brazing

As specialists in honeycomb brazing, we provide solutions widely used in jet engines and land-based turbines. Regardless of your unique requirements or complex designs, our skilled engineering staff is ready to engage in meaningful dialogues, explore your needs, and provide exceptional quality with ultimate customizability for your diverse projects.

Induction & Torch Brazing

For precision and small batch projects, our induction and torch brazing methods offer an ideal solution. Our operators, trained and certified to Byron Products’ high standards, ensure every project meets customer specs and requirements.

Brazing: The Byron Products Way

Byron Products stands at the forefront of innovative brazing techniques and solutions. Our years of experience, combined with our dedication to customer satisfaction, make us your go-to choice for brazing services. Get in touch with us today to discover how our brazing capabilities can answer your needs and exceed your expectations.

Remember, your project is more than just a task to us—it’s an opportunity to offer you solutions that meet your exact specifications and industry standards. Byron Products: Setting the standard for brazing solutions across the industry.

Contact us today to discuss how we can tailor our expertise to meet your specific needs.